- Call Us Today!

- +86-137 2460 7071

- ak01@akexport.cn

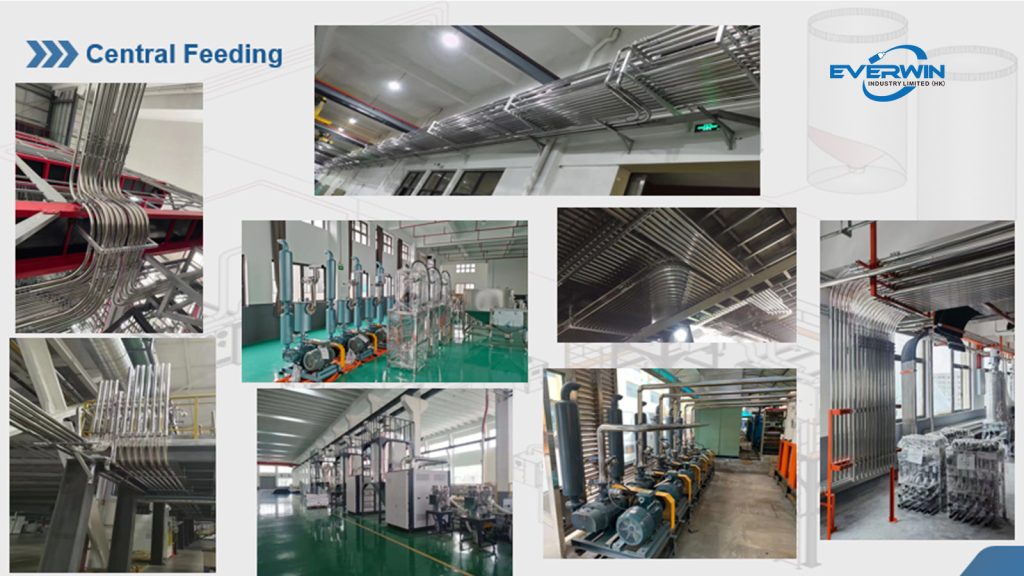

Traditional bottle extrusion blow molding processes often face challenges related to labor-intensive manual feeding, inconsistent material flow, and quality control issues. These factors can lead to inefficiencies, increased costs, and reduced overall productivity. Central feeding system could perfectly help you to solved these problem.Below is the case that we work for one of our customers with the system for 20 sets extrusion blow molding machine.

This whole system helping customer:

1.Saving Labor Cost: US$40,000/year

2.Saving Power: 62,000KW/year

3.Saving Power Cost: US$9,200/year

3.Saving Processing Charges: US$65,000/year

4.Product Qualification Ratio Increased: 1%

5.Total Cost Saving: $114,200/year (He told us, he only spend 18 months to get this whole system money back)

United Kingdom

English

España

Español