- Call Us Today!

- +86-137 2460 7071

- ak01@akexport.cn

Such as chemical container blow molding machine, plastic barrel blow molding machine, stackable oil bottle blow molding machine, engine oil blow molding machine, lubricant oil extrusion blowing mold machine,etc…

To meet the different function of the bottles,we could design from mono layer to multi-layer continuous extrusion die head extrusion blow molding machines.

We can help you design light weight bottles that minimize material usage and reduce your environmental footprint. We have successful case for 5L-110g and 20L-700g.

HDPE, LDPE, PP, Marlex5502, HDPE5201, Tritan, EVOH, Calcium Carbonate, High Molecular Material…etc

Suited for producing large, heavy-duty containers requiring exceptional strength and durability.

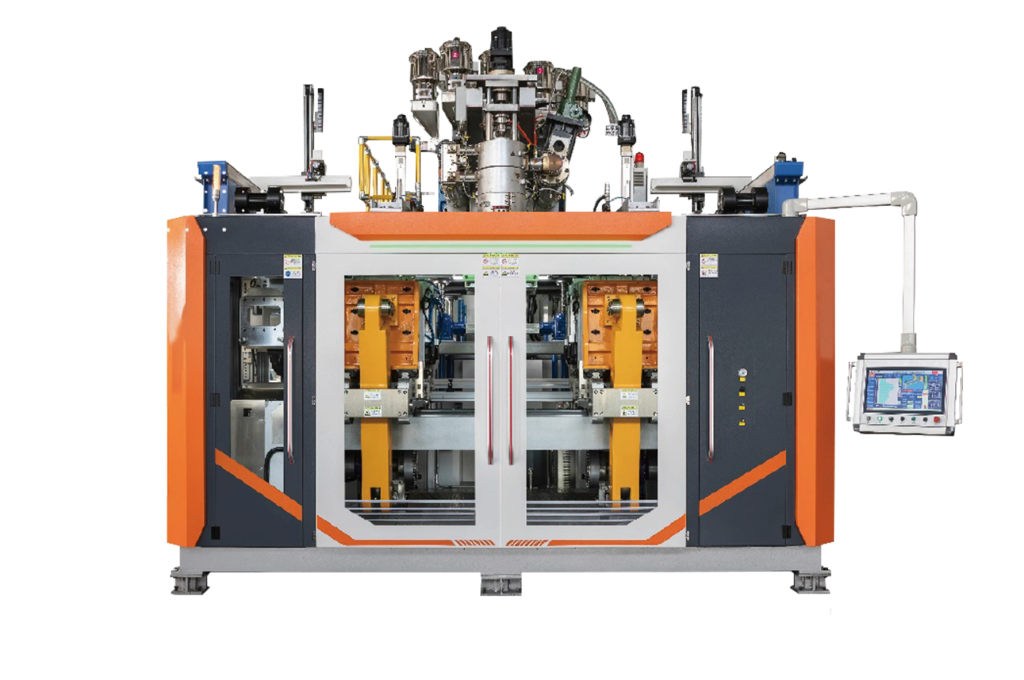

Germany design die head for Double station single head 5 Gallon / 20L extrusion blow molding machine

Full electric extrusion blow molding machine,saving energy,move faster,quite and offer clean environment

Single station extrusion blow molding machine for 10L~30L plastic containers.Which is mainly use for chemical industry or oil industry.Usually for produce engine oil bottles, oil barrels...

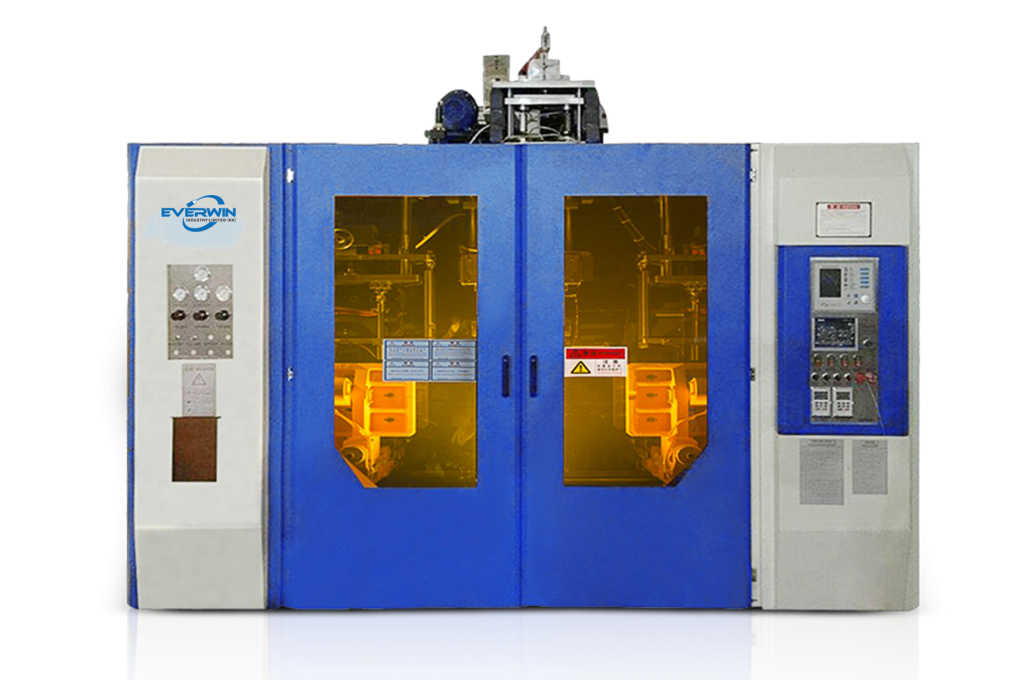

Double station single head jerry can extrusion blow molding machine,with linear guide rail movement for carriage stroke and mold clamping.It could suitable 2L~10L HDPE bottles

A Southeast Asia customer, he want a full automatic production line for one machine. Base on the layout of his workshop and the requirement, we recommend single machine feeding system, and after extrusion blow molding machine produce the bottle, robot hand pick up the bottle and put it on conveyor, then deliver the bottles to test leakage. After that, conveyor transfer the bottle to stacking. With this production line, now he running one shift with only one worker. And a technician for checking the machine time to time. It helping him save a lot of labor cost. At the same time, the full automatic line streamline his production processes.

United Kingdom

English

España

Español